Choosing a flexible colorimeter for your water treatment plant can lead to operating expenditure reductions

Some water quality parameters that must be measured in a water treatment process can only be carried out using colorimetry. This includes the likes of aluminium, iron and manganese.

Colorimetry has been used as an analytical technique for over one hundred years and involves the addition of reagents which then form a coloured complex with the parameter you want to measure.

This colour is then measured using light absorbance and the level of absorbance is proportional to the concentration of the parameter you are trying to measure.

The perceived issue with this analytical technique in water treatment plants today, is the use and expense of the reagents used in the formation of the coloured complex.

What is the issue?

Colorimeters are often provided to work across as large a working range as possible, which is defined by the chemistry being used. This is firstly so that manufacturers can provide a standard product to all users, but also so the colorimeter can be used in various parts of the water treatment process.

The issue with this approach, is that it can lead to excessive amounts of reagents being used. For example, if you are measuring aluminium on final water, you may only typically have less than 0.1mg/l in your sample, but your colorimeter may be setup to measure up to 0.4mg/l. This means the colorimeter is adding excessive amounts of reagent every test.

How can a flexible colorimeter platform reduce reagent consumption?

By utilising a flexible, configurable colorimeter, the reagent addition can be changed to suit the application which means users can reduce the reagents if the working range required is smaller than the chemistry is actually capable of.

A flexible colorimeter is a wet chemistry platform which can be changed depending upon

- The parameter that needs to be measured

- The application which it is to be used in

- The working range required for that particular application

What level of savings can be made?

If we use Iron measurement in final water as an example, we can demonstrate the kind of reagent savings that are possible.

The TPTZ chemistry is often used for iron measurement in water treatment plants and is often set up to measure from 0-1000ppb.

However, in final water, the typical levels of iron are less than 200ppb.

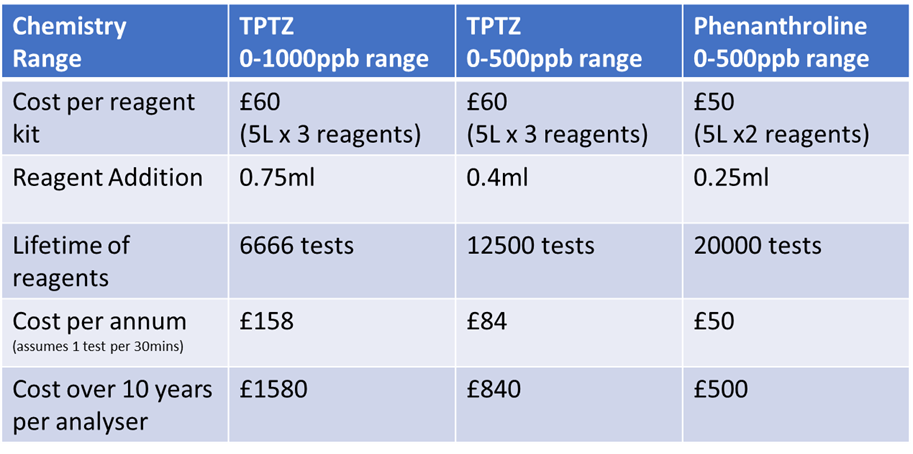

If the range of the colorimeter is set up to a 0-500ppb range, which still gives plenty of room above the PCV level for Iron, the amount of reagent used per analysis can be cut by approximately 50%. If we assume a TPTZ reagent kit costs £60, then this leads to a saving of approximately 50% per year, as detailed in the table below.

However, we can make further cost savings by changing the chemistry used for Iron analysis. There are three iron chemistries typically used. Ferrozine, TPTZ and phenanthroline. The phenanthroline chemistry has a larger working range than either TPTZ or ferrozine and as such, the reagent addition for this chemistry can be reduced even further. In addition, the kit cost for phenanthroline tends to be slightly cheaper than that of TPTZ so the cost savings can be as high as 69%.

In addition, reducing reagent consumption also means fewer reagent changes per year, reducing the number of times operators need to change the reagent bottles meaning less waste, and less operator time consumed by such activities.

To summarise, a simple conversation with your supplier about the application and the actual range in that sample can lead to cost savings.

PMA offer two different flexible colorimeters, which is best depends upon your application.

Find out more using the buttons below

Knowledgeable, experienced staff.

Need some advice or support? We’re here to help.

If you need a call back about how Process Measurement and Analysis can help you or have any questions at all please feel free to contact us at [email protected]. A member of our experienced team will contact you directly.