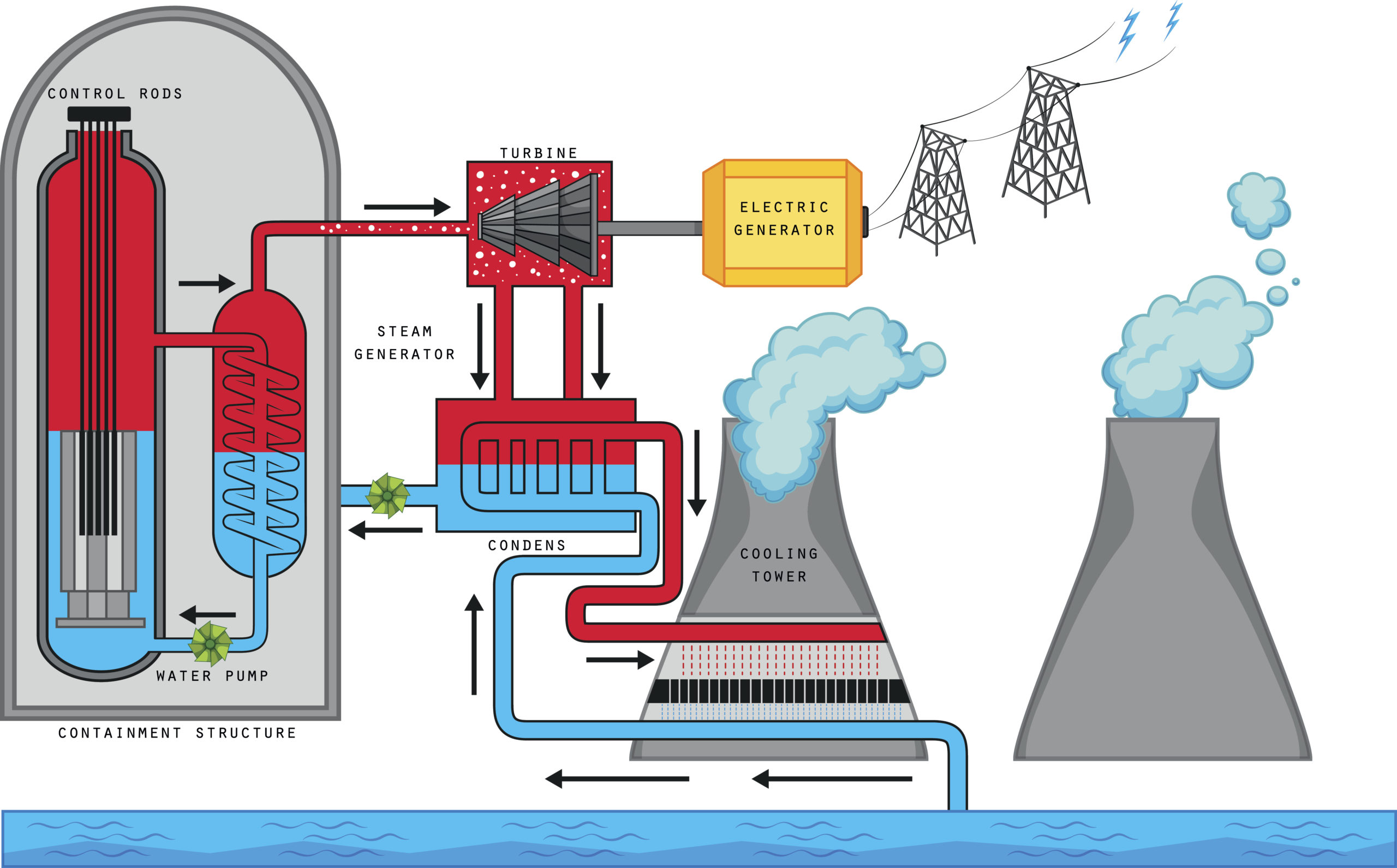

Water moving through a power plant must be carefully monitored.

In boilers, it must be extremely high quality, since it affects both performance and the overall boiler life

Corrosion in the power plant steam generation process is the primary cause of downtime. Online monitoring of corrosion chemistry enables operators to act when early warning signs are observed.

Every site and every system is different, but using online analysis for key water quality parameters, control can be achieved and downtime reduced, efficiency maximised, repair costs minimised and the health and safety of personnel protected.

At PMA we have a range of instrumentation ideal for online monitoring of water quality in power plants.

Silica

When ion exchange units or mixed-bed polishers approach the end of their life, silica is the first impurity to breakthrough. Monitoring silica rather than conductivity is a far more effective early warning system for determining that the demineraliser needs attention.

Silica build up on the turbine blades from silica carryover in steam can result in inefficient and imbalanced spinning that directly affect power output.

Find out more about the 3S silica online analyser for power plants

Iron

Flow-accelerated corrosion (FAC) of the metal components in power plant water-steam circuits reduces the lifetime of water-exposed carbon steel pipework and copper heat exchangers. Online turbidity monitoring of water has been used as a more effective measurement of iron particulate content than online iron monitors. This is because although some chemistries used in online iron colorimeters are aggressive and able to measure iron particulates, they may not be able to digest all of them without a digestion step. Nephelometric turbidity measurement has been shown to be a suitable surrogate measurement for these non-digestable iron oxides. Used in combination with an online iron analyser which can also measure any dissolved iron content and a full understanding of the level of corrosion can be achieved.

Find out more about FAC control

Sodium

Online sodium measurement has become one of the key water quality measurements in the steam and water cycle of power plants. Whether measuring sodium post demineralisation, the condensate or elsewhere, low ppb sodium measurement becomes key in understanding water quality in the plant. Measuring sodium post cation resin demineralisation for example, can ensure no cation breakthrough and optimise regeneration processes.

Find out more about the 3S sodium analyser for power plants

Can’t see the parameter you want to measure?

We can offer instrumentation for conductivity, copper, pH, DO, ORP, Chloride, molybdate, chlorine, oil in water/hydrocarbons, zinc, hardness, phosphate and more.

Review all the parameters we at PMA can offer on our parameters page.

Knowledgeable, experienced staff.

Need some advice or support? We’re here to help.

If you need a call back about how Process Measurement and Analysis can help you or have any questions at all please feel free to contact us at [email protected]. A member of our experienced team will contact you directly.