A number of innovative pilot plants have been rolled out across Northern Ireland Water to help achieve MCPA and organics removals targets as part of it’s PC21 business plan.

The mobile plants are run in parallel to the main works and allow for experimentation with the specific raw water at each plant without any adverse effect on the main plant.

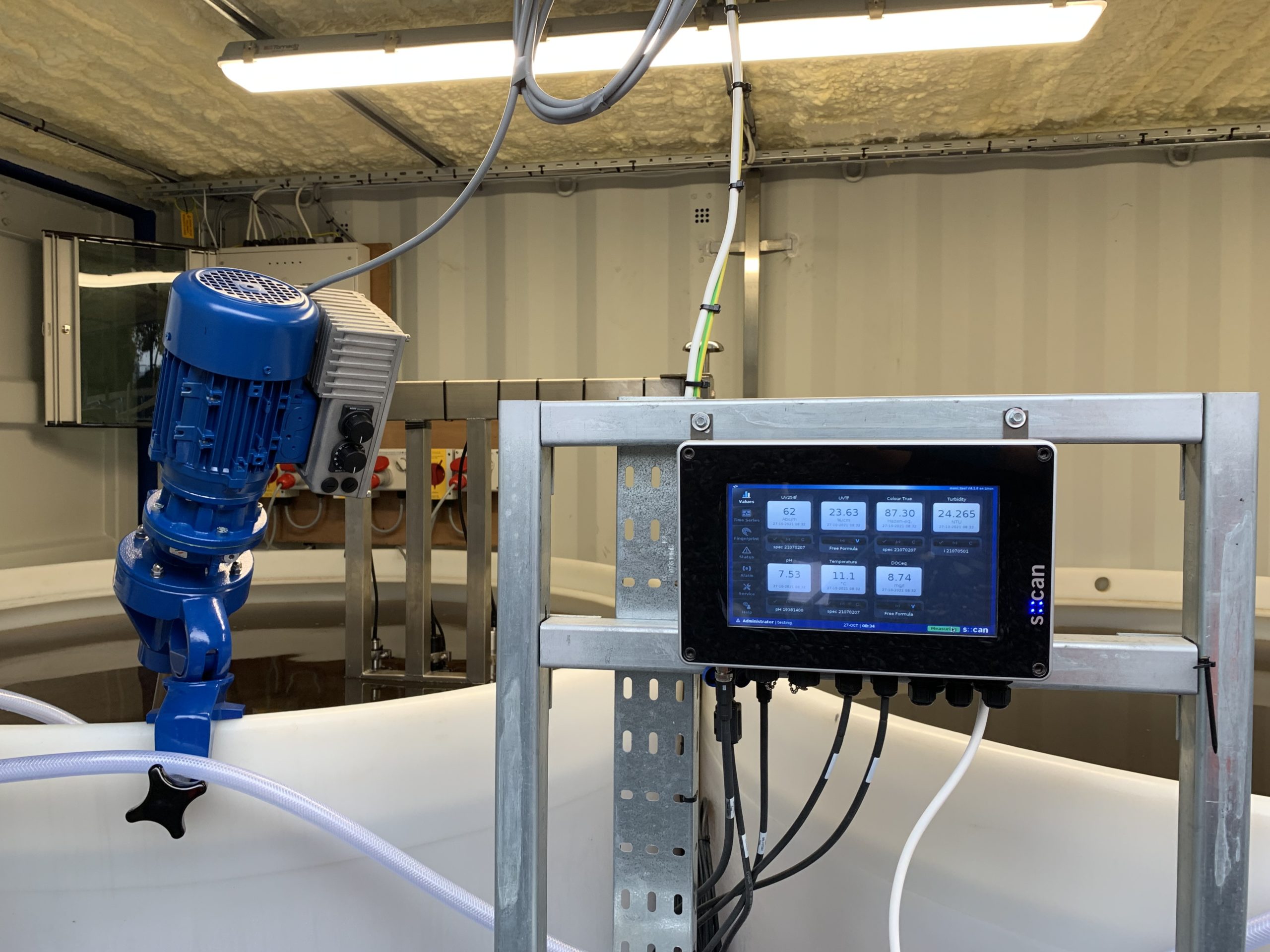

Each pilot plant utilises different treatment technologies including DAF, clarifier and ion exchange and all of them utilise s::can sensors to measure the efficacy of the treatment process.

Each plant has a s::can spectro::lyser measuring UV254, DOC and colour on the raw water. In addition, an i::scan and a pH::lyser are used to monitor turbidity, pH and temperature.

The s::can spectro::lyser is a fully submersible UV-Vis spectrophotometer with a unique approach to turbidity compensation. This enables the sensor to accurately measure UV254 and true colour in a variety of different water sources without frequent recalibration. As the plants will be used on a number of different sites, each with their own raw water characteristics, the use of the spectro::lyser ensures accurate measurement across multiple parameters, with minimal effort from the on site team.

On the post treatment sample, an i::scan is used for measuring UV254, %UVT and turbidity. This enables Northern Ireland Water to be able to assess the efficacy of each treatment process.

For more information on the pilot plants, check out the video.

Video courtesy of Northern Ireland Water. Special thanks to Trevor Cousins (Innovation Manager, Northern Ireland Water)

Need some advice or support? We’re here to help.

If you need a call back about how Process Measurement and Analysis can help you or have any questions at all please feel free to contact us at [email protected]. A member of our experienced team will contact you directly.